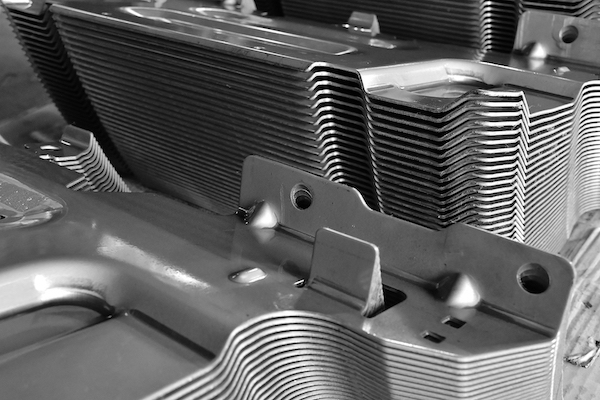

Sheet Metal Stamping

We designed our facility to offer a turn-key operation to meet all your sheet metal stamping needs.

Custom sheet metal parts and assemblies in as fast as 1 day. Get an online quote today.

Certifications

ISO 9001: 2015 IATF 16949: 2016

37,000+

Parts fabricated each month

50,000+

Product developers served

1,000+

parts within days

Sheet Metal Stamping Services

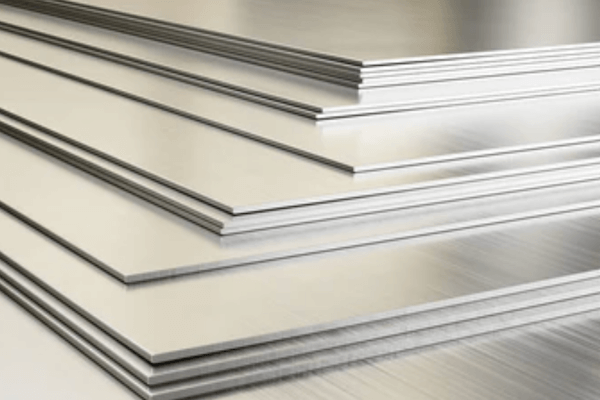

Wide range of materials

T1 samples as fast as 10 days with low minimum order quantities.

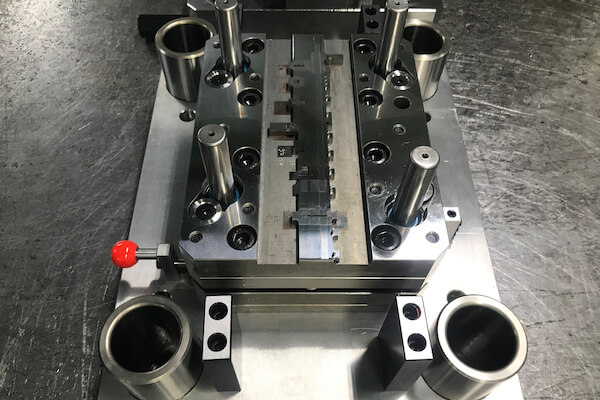

Low volume forming tools

Tight tolerances and finishing capabilities, as fast as 2 days.

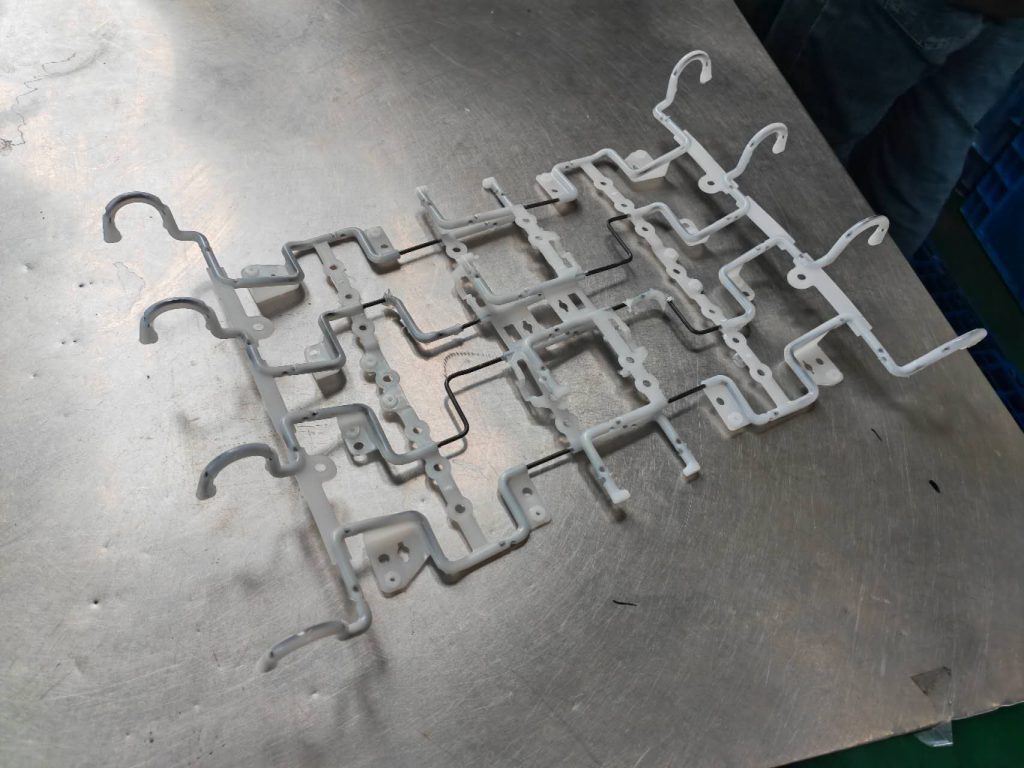

Welding assembly and wire bending

Add multiple finishes to your part such as anodizing or powder coating.

Inserts, post machining and surface finishes

Production quality parts without the tooling investment.

Sheet Metal Stamping Services Applications

Automotive Structures

IATF 16949 certified, we are trusted to manufacture high-quality components to meet every customer’s needs.

Seat Suspension Mat

We manufacture high quality seat suspensions mats

Electronic Housings

We can provide stamped and fabricated metal parts in a range of sizes. No design is too simple or too complex.

Top 5 Manufacturing Technologies That Increase Efficiency and Speed

Why choose RP Group for sheet metal?

Low to High Volume Production

We work with your CAD files during sheet metal production to produce accurate parts in prototype quantities as low as one or as high as several hundred.

Communication

We are always quick to respond to questions via email, phone, web meeting or chat to ensure your project is turned around as fast as possible. All project history kept on our secure online portal.

Automated reports

We provide progress and tracking information through our customer portal. Videos and photos of the parts can be confirmed before parts are shipped out.

Design for Manufacture

Our experienced engineers will analyse your design and provide feedback on manufacturability and look for opportunities to reduce cost.

Manufacturing Speed

At RP Group we have in-house rapid prototyping as well as mass production capabilities which has helped our customers accelerate their products to market.

Full Service Manufacturing

We offer a wide range of materials, processes, finishes and sub-components to make us your one-stop supplier for your entire project.

Sheet Metal Stamping FAQs

Sheet metal stamping can be referred to as any of a number of metal forming operations such as stamping, bending, pressing, folding, and stretching used to produce the final part.

All metal stamping processes use punch presses with custom-made tooling and dies to produce a shape, pattern, or other characteristic to produce a part. Generally, sheet metal stamping can provide tighter tolerances than metal fabrication. It is also a fast and cost-effective way to produce high volume metal parts.

Absolutely. We can pierce, form, and finish parts that you provide.

We can produce prototype orders of 1 to full production runs of over 1 million pieces a year.

Yes. We can provide finishing services which meet our customers' most demanding specifications.