Online 3D Printing Service

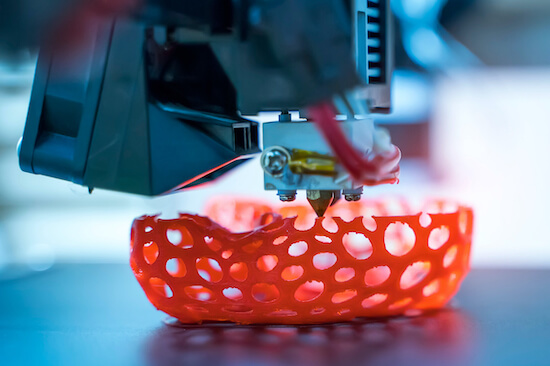

At RP Group, you can make complex products that were previously impossible to make using traditional manufacturing.

RP Group lets you choose from advanced 3D printing materials and technology. We also provide feedback for 3D print files from the sketch to the finished product.

Available now direct from the USA!

Certifications

ISO 9001: 2015

IATF 2016:16949

160+

Countries serviced

10+

3D printing technologies

90+

3D printing materials

3D printing processes and materials

Selective Laser Sintering [SLS]

High level of accuracy, relatively cheap raw material, and high temperature resistance make it perfect for a wide range of structural engineering applications.

Materials available: Nylon PA12, Nylon PA12 with glass beads

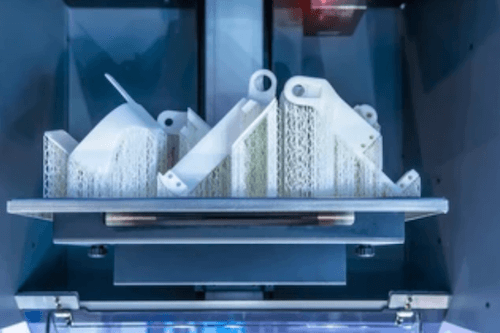

HP Multi Jet Fusion [MJF]

Multi Jet Fusion can produce functional nylon prototypes and end-use production parts in as little as one day.

Materials available: Nylon PA12, Nylon PA12 with glass beads and polypropylene (PP)

Stereolithography [SLA]

Stereolithography (SLA) creates parts in a layer-by-layer fashion by using photochemical processes whereby light causes chemical monomers to link together to form polymers.

Materials available: ABS natural and ABS clear stimulants.

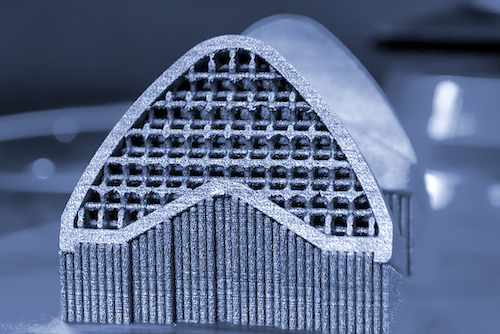

Binder Jetting

In binder jetting, a binder is selectively deposited onto the powder bed which bonds these areas together. This forms a solid part one layer at a time.

Materials available: Stainless Steel 17-4PH, Stainless Steel 316L, Steel and Sandstone.

Laser Powder Bed Fusion Metal (LPBF-M)

Selective Laser Melting (SLM) process uses a laser to scan and selectively melt the metal powder particles, bonding them together and building a part layer-by-layer.

Material available: Aluminum.

Wax Casting

3D printing technologies create a smooth wax pattern, which is used to create casting molds to produce precious metal parts.

Materials available: Brass, bronze, copper, gold, platinum, silver

Leading-Edge Manufacturing Technology

We use the most advanced manufacturing technology and materials from cutting-edge industry leaders

3D Printing Materials

Plastics

- Acura 60

- Acura Xtreme

- Acura Xtreme 200

- Fine Detail Plastic

- High Definition Full Color

- MJF Plastic PA12

- MJF Plastic PA12GB

- Nylon 6 Mineral Filled

- PA11

- Sandstone

- TPU

- Versatile Plastic

- Wax

Metals

- Aluminium

- Steel

- Stainless Steel 316L

- Stainless Steel 17-4PH

- Bronze

- Brass

- Copper

- Gold Plated Brass

- Gold

- Platinum

- Rhodium Plated Brass

- Silver

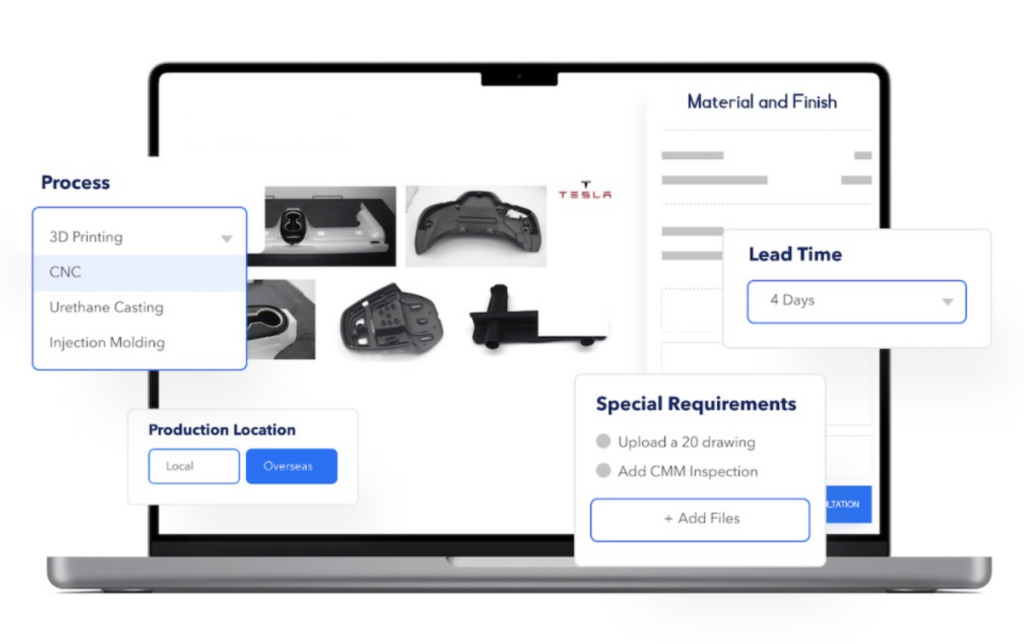

Instant Online Quoting

Prototyping is all about speed so provide the ability for customers to upload and get an instant feedback on costs and then place an order with less hassles.

- Select from a wide range of materials.

- Compare pricing options instantly

- Manage quotes and orders in online portal

How to get a quote and order

Why RP Group for your 3D printed parts?

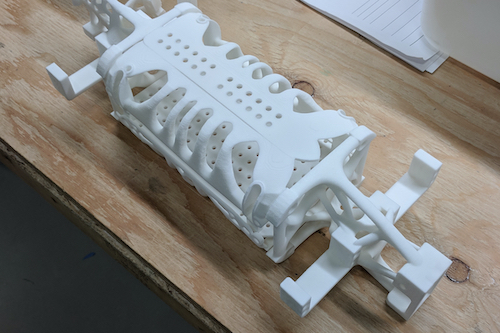

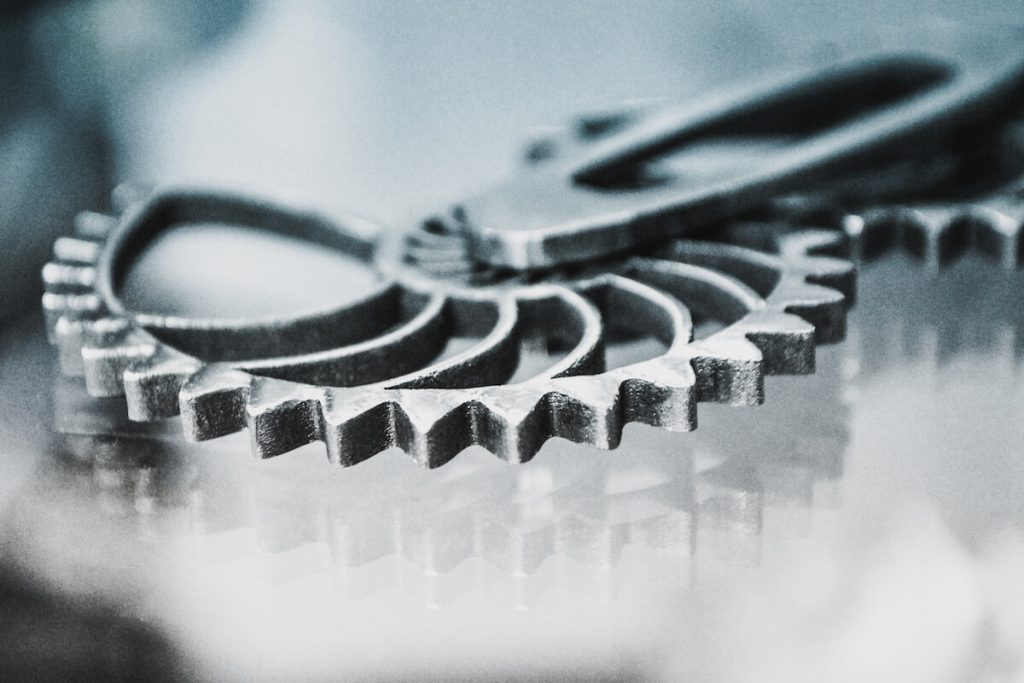

Assembly Time

The advantage of 3D printing parts is complex shapes can be created which enables you to combine multiple separate parts together to save on cost and time..

Quick Turnaround

Get a quote and order parts within minutes receive them in a couple of days (sometimes next day!). This enables you to make multiple iterations to your design very fast.

Quality Reports

We the latest cutting edge technology and our highly trained US operators and quality engineers ensure consistent high quality.

Latest Technologies

At RP Group we pride ourselves as being one of the most advanced manufacturer in the world. We use the most reputable brand 3D printing equipment such as BASF, HP, EOS, and ExOne.

Material Selection

We have one of the largest ranges of 3D printing materials in the industry. 75+ materials available and the list is growing! Please reach out to one of our engineers to help you with the material selection process.

More than 3D printing

RP Group is more than a 3D printing or prototyping company. We have more than 10 years of in house experience of launching products into mass production with full EMS assembly capability. We can help you find issues early that will have a big impact on costs and quality.

Top 5 Manufacturing Technologies That Increase Efficiency and Speed

Online 3D Printing FAQs

Plastic:24" x 28" x 18" (609 x 711 x 457 mm) via SLA process in Accura 60 which is a tranlucent rigid plastic and Accura Extreme 200 which is a high-strength plastic.

Metal: 30" x 15.5" x 15.5" (762 × 393 × 393 mm) in Steel via Binder Jetting technology.

Uploading your files to our online quoting software ensures there are no confusion over what file versions are being used for your build and makes the whole ordering process a lot faster. To upload a file is easy:

1) Sign up for an account (button in top right corner). If you have already signed up then you can skip this step.

2) Log in to your online account.

3) Click on 'Create a new project' or the 'Create a new quote' button.

4) Click on the 'Upload a file' button or simply drag the file into the window.

5) You can add as many file you would like and when you are done click on the 'Next' button on the bottom. You will then be then taken to where you can configure the processes, materials, quantities and finishes for you parts.

Ordering parts parts is easy. Please follow the below steps:

1)First log into your Nexuvo account and open the quote that you want to order parts from.

2) You can further configure the part quantity, material, process and surface finishes.

3) Check to make sure all details are correct. The scale or part size may some time be out due to the units in the file or it is corrupted during the upload process. You can click on the 3D preview button to check the part for missing surfaces and features.

4) Check if the part count for each part model is more than 1. If the part is intended to be only one part then please fix the file and upload the new version. Click the 'Update File' button.

5) If you are happy with all the parts configuration you can click on the add to cart button. If there parts that you don't want to order then you can either delete them by clicking on the delete icon or just select the part you clicking on the check box next to each part.

IMPORTANT: If you want to order a model in different sizes, you need to upload the 3D file for each size.

6) Next you will be taken to an order confirmation page. Please check that all details are correct but if you need to make further changes you can press the 'Edit my order' to configure, delete or add parts as needed. Choose a manufacturing lead time that is available and a shipping speed option. Select your shipping address or create a new one.

7) Click the 'Proceed to Checkout' button and enter your payment details. Add any additional information in the Comments field and click the "Place my Order" button.

Simply log into our online quoting software to find out the status of your parts. You will also be assigned a project manager who will be able to provide you the status and answer any questions you may have.